Transform Your CAE Simulation and Design Workflow

Transform your CAE simulation and design flow by integrating advanced tools and features automating tasks to reach appropriate results. Accurate simulations allow you to significantly reduce the number of prototypes needed in your development process

The core function of CAE solutions is to minimize prototype iterations by providing reliable simulations. This includes conducting stress analysis and both static and dynamic evaluations across various sectors, such as automotive, aerospace, medical devices, and other industrial applications.

At Varphi, our expertise encompasses a wide range of CAE solutions, including structural analysis, aerodynamics, thermal analysis, and safety assessments, ensuring comprehensive support for your design needs.

Advanced Engineering Solutions provided by our CAE, CFD & FEA experts

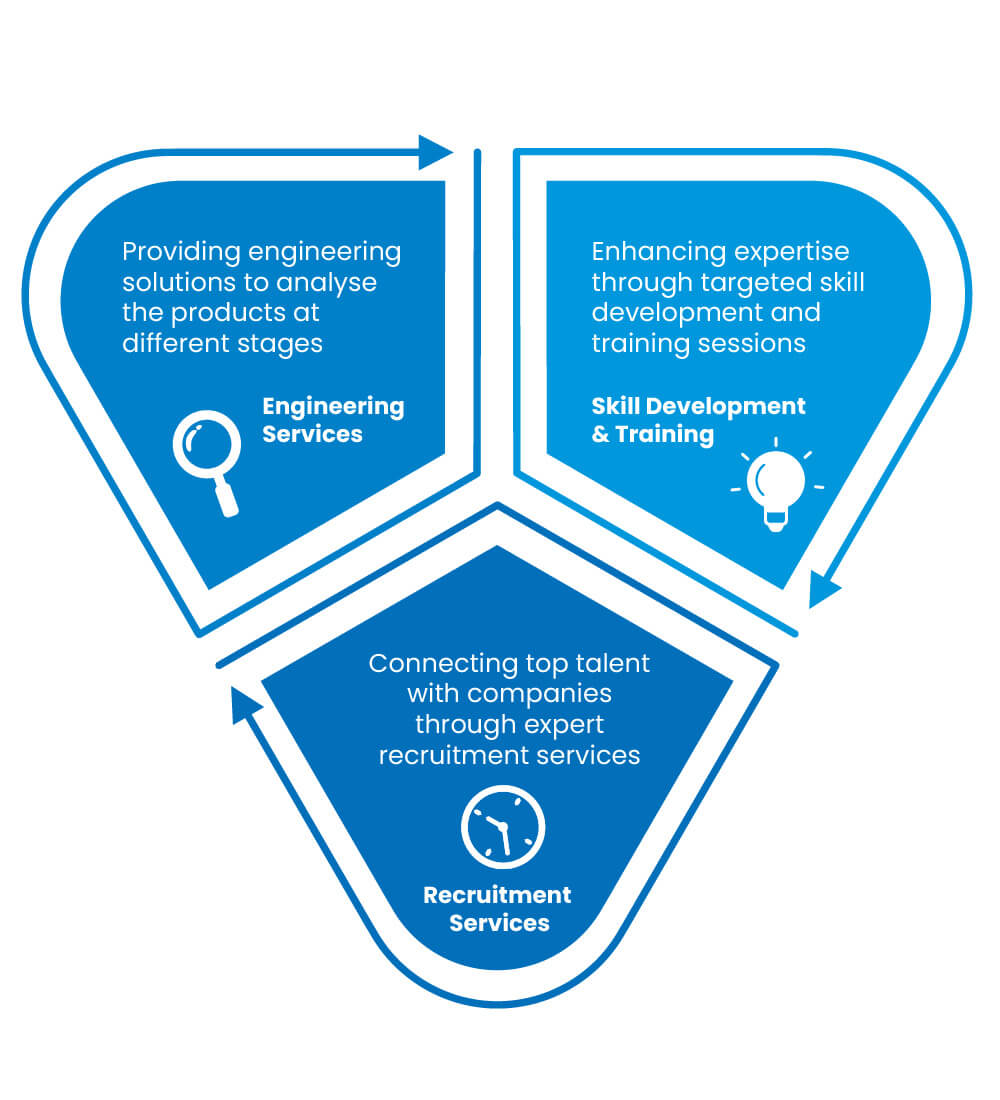

We deliver Advanced Engineering Services for Product Development, Systems Engineering and Manufacturing Engineering.

LEADING INDUSTRIAL SOLUTIONS PROVIDER INDIA

With exceptional service and expertise in technology and innovation

Improvise your products and optimize workflows with our advanced Computer-Aided Engineering (CAE) and Computational Fluid Dynamics (CFD) solutions.

CAE Solutions

CAE Solutions

Our CAE solutions leverage advanced simulation and analysis tools to optimize product designs, improve performance, and reduce development time. These solutions empower engineers to make data-driven decisions and enhance overall efficiency.

CFD Solutions

CFD Solutions

Computational Fluid Dynamics (CFD) uses numerical methods to analyze fluid flow, heat transfer, and related phenomena. It enables engineers to visualize and optimize designs for enhanced performance and efficiency.

FEA Solutions

FEA Solutions

Our FEA (Finite Element Analysis) solutions offer powerful simulation tools to assess structural integrity, predict behavior under various conditions, and optimize designs. This approach helps engineers ensure safety, enhance performance, and reduce costs effectively.

Product Development Cycle

Get in Touch

If you’ve got questions or ideas you would like to share, send a message. For anything more specific, please use one of the addresses listed below.

Pune, India

U15, Runwal Platinum, NDA Road, Bavdhan, Pune, Maharashtra – 411021.

Find Us on Map

Chennai, India

320/B, Thiruvallur high road, Chennai,

Tamil Nadu – 600124

Find Us on Map

Support

+91-82618 81518

+91-99433 04676

Our Email

info@varphi.in

Let's Talk About Your Project

After we get some information from you, we’ll set up a time to discuss your project in further detail.